无机材料学报 ›› 2022, Vol. 37 ›› Issue (8): 841-852.DOI: 10.15541/jim20220002 CSTR: 32189.14.10.15541/jim20220002

所属专题: 2022年度中国知网高下载论文

陈勇强1( ), 王怡雪1, 张帆1,2, 李红霞1,3, 董宾宾4, 闵志宇4, 张锐1,4(

), 王怡雪1, 张帆1,2, 李红霞1,3, 董宾宾4, 闵志宇4, 张锐1,4( )

)

收稿日期:2022-01-04

修回日期:2022-03-08

出版日期:2022-08-20

网络出版日期:2022-03-29

通讯作者:

张 锐, 教授. E-mail: zhangray@zzu.edu.cn作者简介:陈勇强(1991-), 男, 博士, 讲师. E-mail: chenyq@zzu.edu.cn

基金资助:

CHEN Yongqiang1( ), WANG Yixue1, ZHANG Fan1,2, LI Hongxia1,3, DONG Binbin4, MIN Zhiyu4, ZHANG Rui1,4(

), WANG Yixue1, ZHANG Fan1,2, LI Hongxia1,3, DONG Binbin4, MIN Zhiyu4, ZHANG Rui1,4( )

)

Received:2022-01-04

Revised:2022-03-08

Published:2022-08-20

Online:2022-03-29

Contact:

ZHANG Rui, professor. E-mail: zhangray@zzu.edu.cnAbout author:CHEN Yongqiang (1991-), male, PhD, lecturer. E-mail: chenyq@zzu.edu.cn

Supported by:摘要:

特种陶瓷广泛应用于航天航空、电子信息、新能源、机械、化工等新兴工业领域, 其高温制备过程仍以传统燃气窑炉和电加热炉为主; 碳排放高、能耗大, 节能减排形势严峻。当前, 我国面临实现“双碳”目标的巨大压力, 研究推广清洁高效的加热技术迫在眉睫。微波加热是利用材料自身对微波进行吸收, 将电磁能转化为热能, 能量的转移发生在分子水平上, 通过这种方式, 加热在整个材料内外同时产生, 整个材料体系中的温度梯度非常低。除体积加热外, 选择性加热、功率再分配、热剧变以及微波等离子效应等也是微波烧结的显著特征。微波加热具有节能环保、改善制品性能、减少燃烧碳排放等优点, 国内外有许多关于微波合成各种氧化物、碳化物、氮化物陶瓷粉体和微波烧结陶瓷复合材料的报道。本文首先对微波和微波混合烧结的基本理论进行综述, 然后介绍了微波加热制备陶瓷粉体与微波烧结制备陶瓷材料的最新研究进展, 最后总结了微波加热在陶瓷工程制品烧结中的一些研究成果, 体现出微波烧结的优越性, 并提出了微波烧结制备特种陶瓷的关键问题和今后的发展方向。

中图分类号:

陈勇强, 王怡雪, 张帆, 李红霞, 董宾宾, 闵志宇, 张锐. 微波加热制备特种陶瓷材料研究进展[J]. 无机材料学报, 2022, 37(8): 841-852.

CHEN Yongqiang, WANG Yixue, ZHANG Fan, LI Hongxia, DONG Binbin, MIN Zhiyu, ZHANG Rui. Preparation of Special Ceramics by Microwave Heating: a Review[J]. Journal of Inorganic Materials, 2022, 37(8): 841-852.

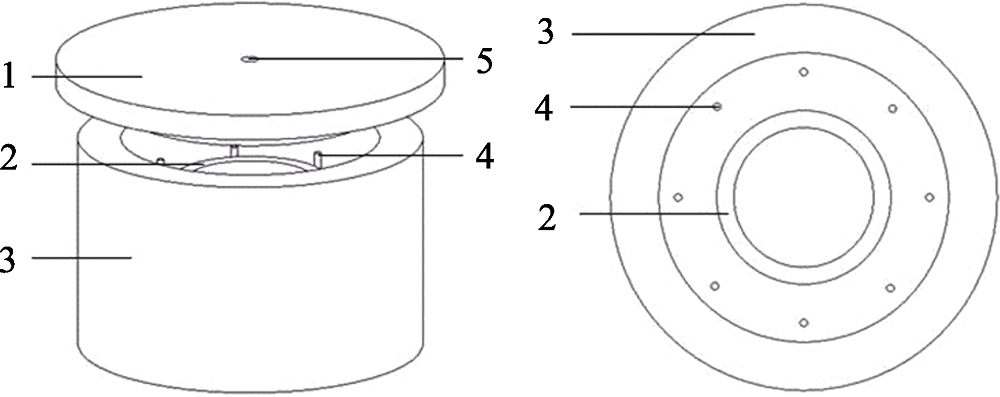

图2 微波热解制备α-Al2O3粉体的保温结构示意图[44]

Fig. 2 Schematic diagram of the insulation structure of α-Al2O3 powder prepared by microwave pyrolysis[44] (1—High alumina lightweight mullite foam brick head cover; 2—95 alumina crucible; 3—High alumina lightweight mullite foam brick insulation cylinder; 4—SiC auxiliary heating rods; 5—Infrared thermometer hole)

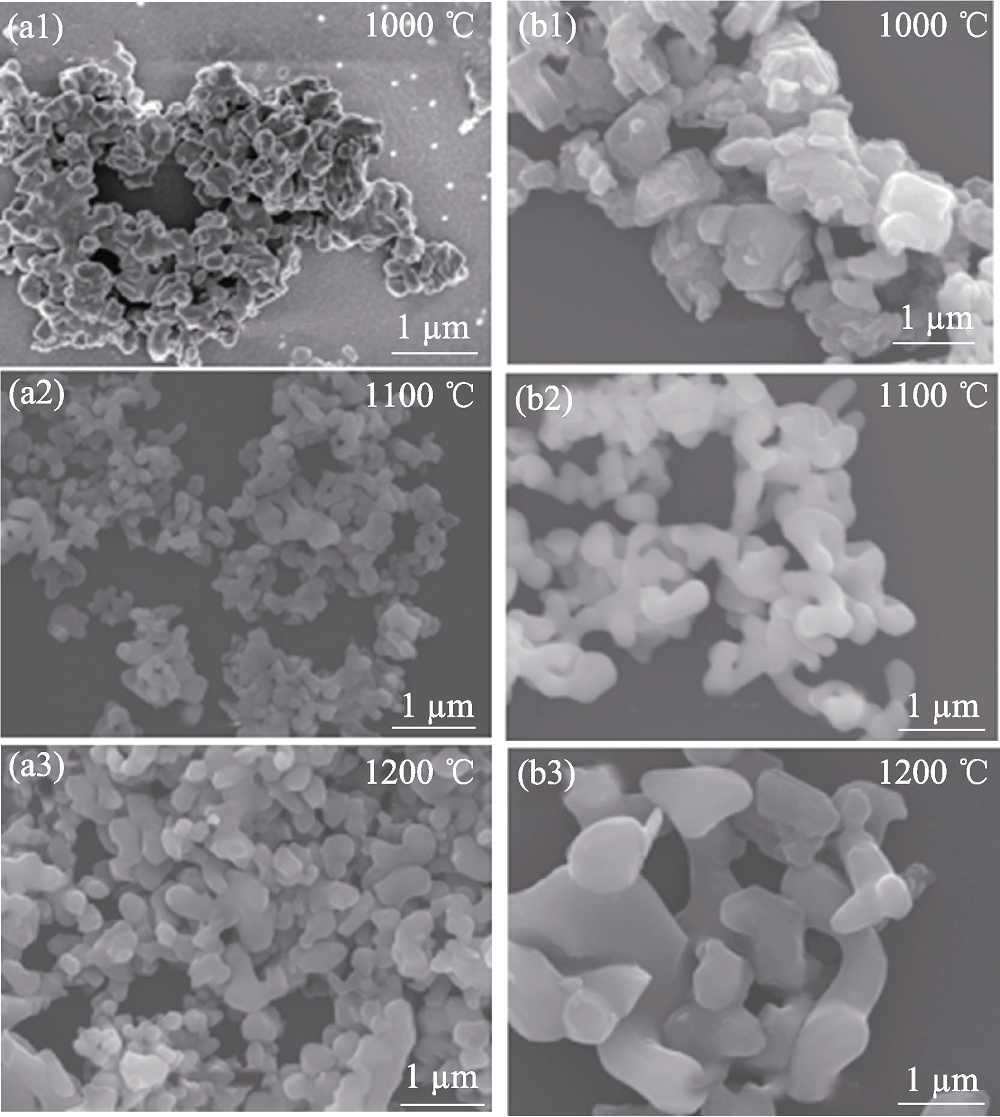

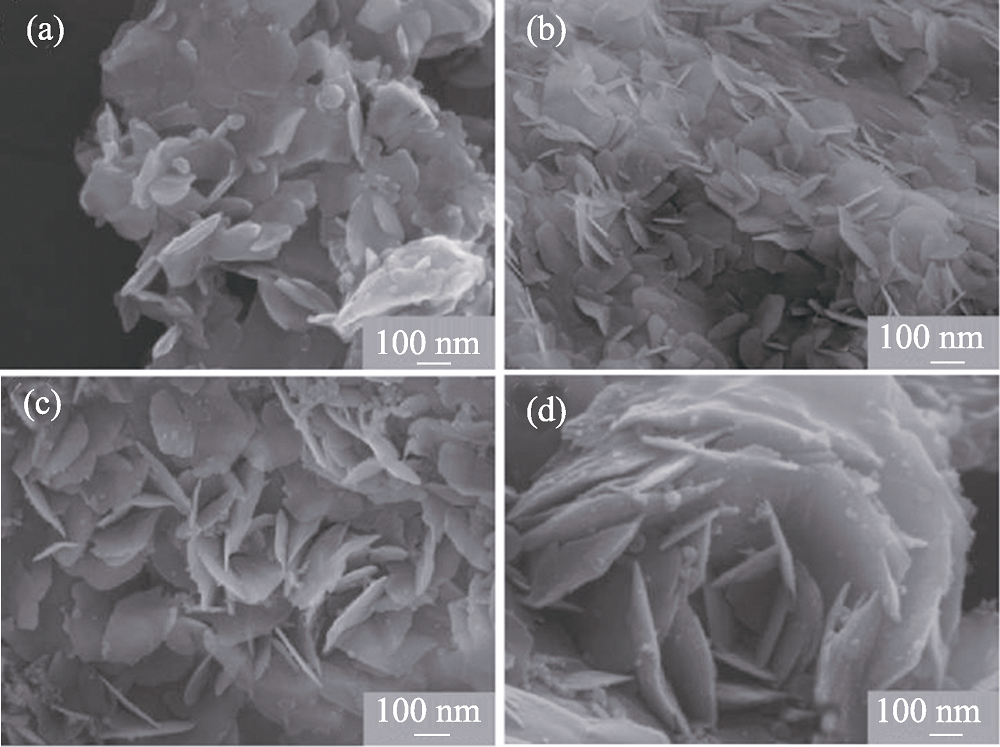

图3 两种前驱体粉料在不同温度下微波热解所得样品的SEM照片[44]

Fig. 3 SEM images of samples obtained from microwave pyrolysis of two precursor powders at different temperatures [44] (a) Aluminum ammonium sulfate dodecahydrate as prcursor, (b) Aluminum hydroxide as precursor

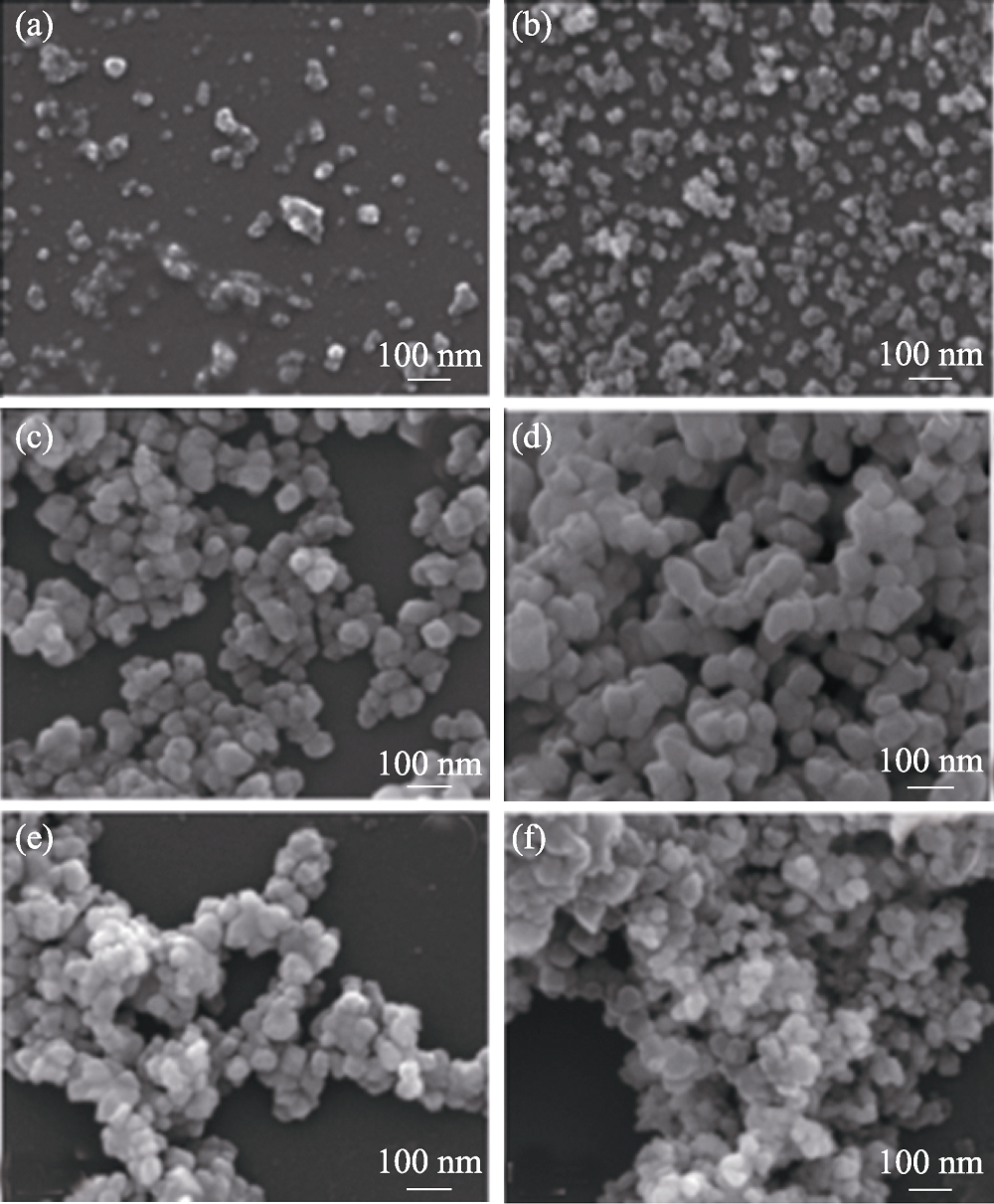

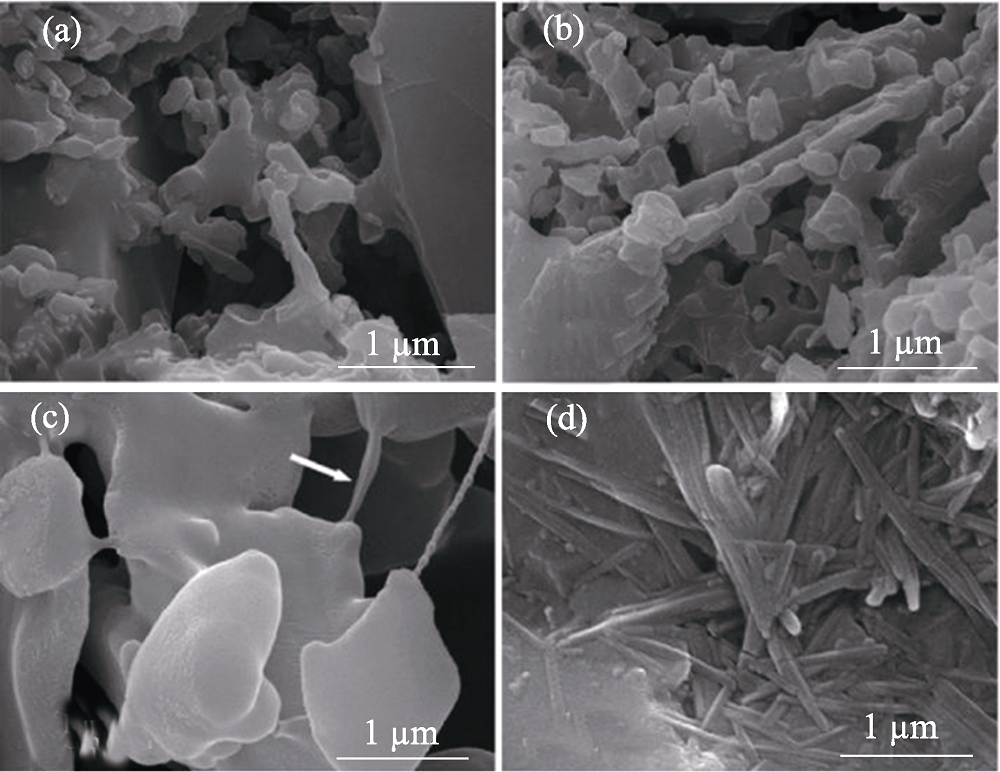

图4 不同微波热解温度和750 ℃常规热解获得氧化锆粉体的SEM照片[45]

Fig. 4 SEM images of zirconia powders obtained at different microwave pyrolysis temperatures and conventional pyrolysis at 750 ℃[45] (a) 700 ℃; (b) 750 ℃; (c) 800 ℃; (d) 850 ℃; (e) 900 ℃; (f) conventional pyrolysis at 750 ℃

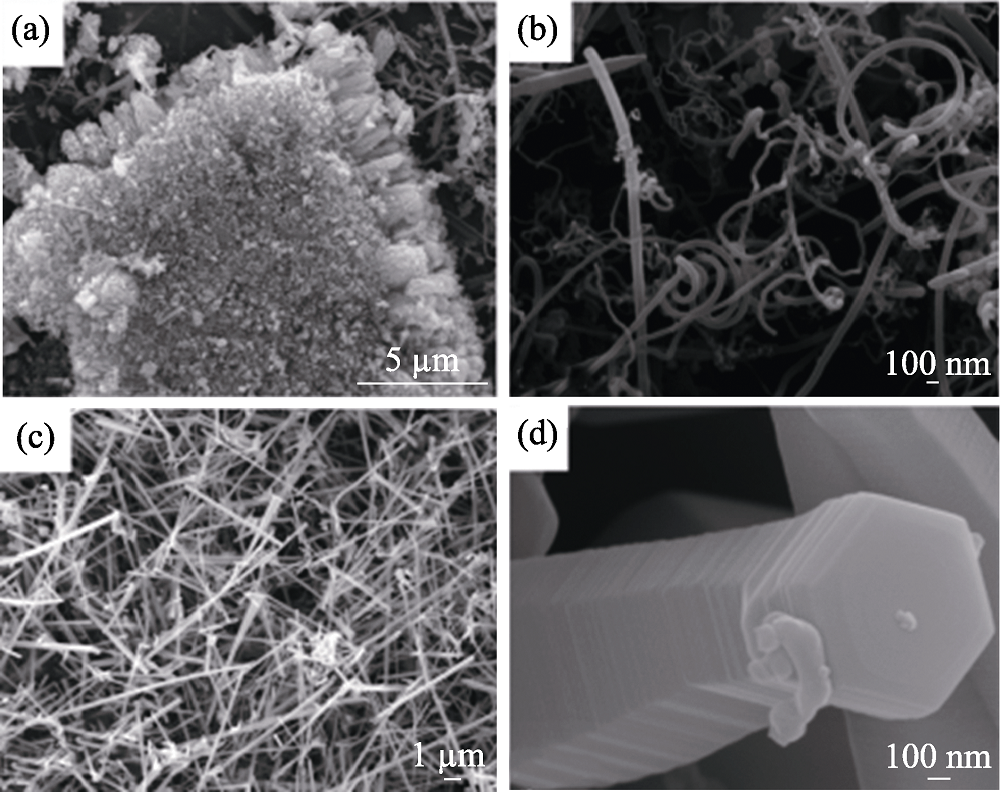

图6 微波加热至1100 ℃并保温30 min, 合成SiC晶体的SEM照片[56]

Fig. 6 SEM images of the synthesized SiC crystals by microwave heating at 1100 ℃ and holding for 30 min[56] (a) Spatial growth of SiC crystals; (b) SiC transistors; (c) SEM images of SiC whiskers at (c) low magnification and (d) high magnification

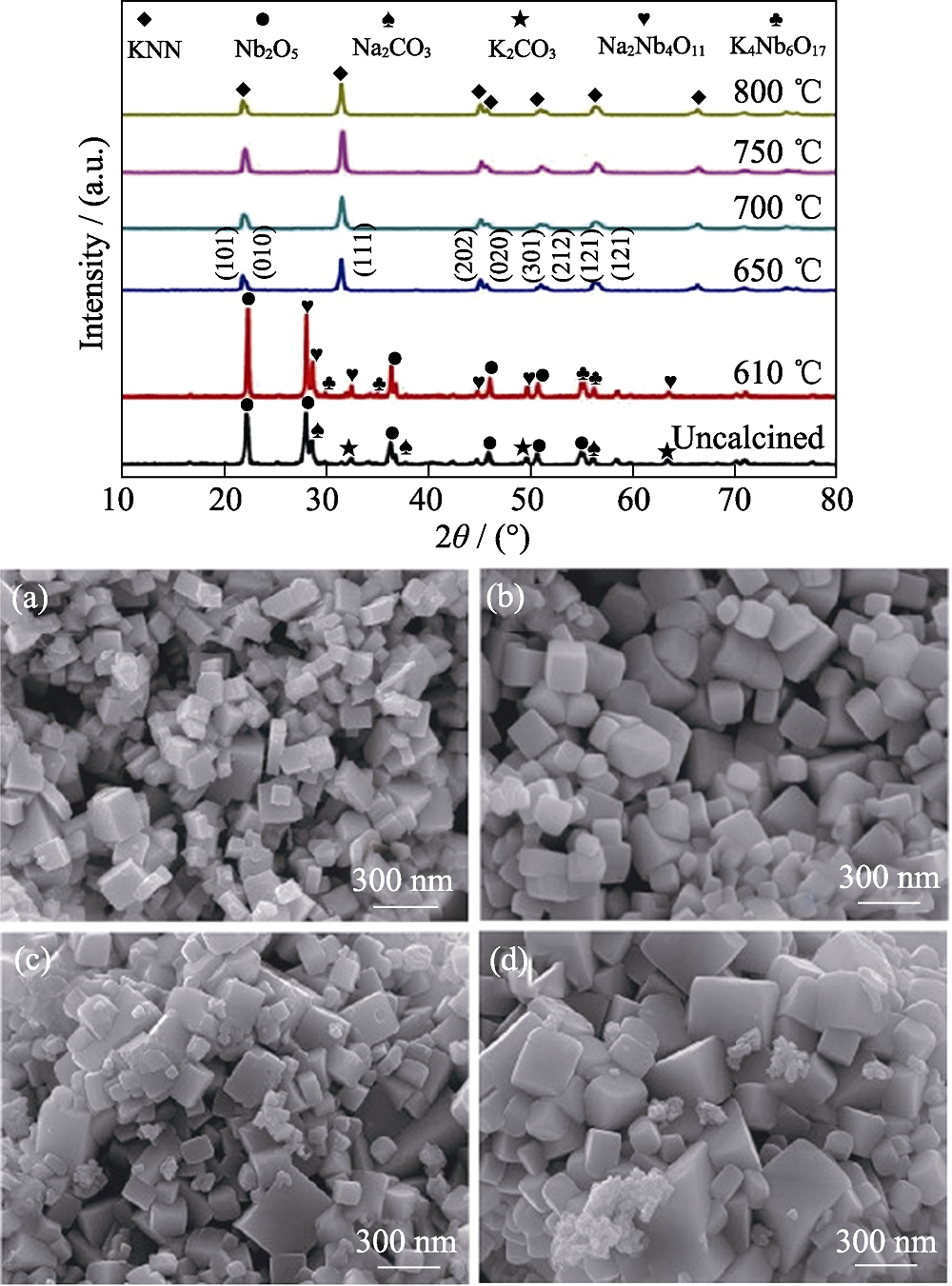

图7 不同温度微波加热合成KNN的XRD图谱和SEM照片[61]

Fig. 7 XRD patterns and SEM images of KNN synthesized by microwave heating at different temperatures[61] (a) 650 ℃; (b) 700 ℃; (c) 750 ℃; (d) 800 ℃

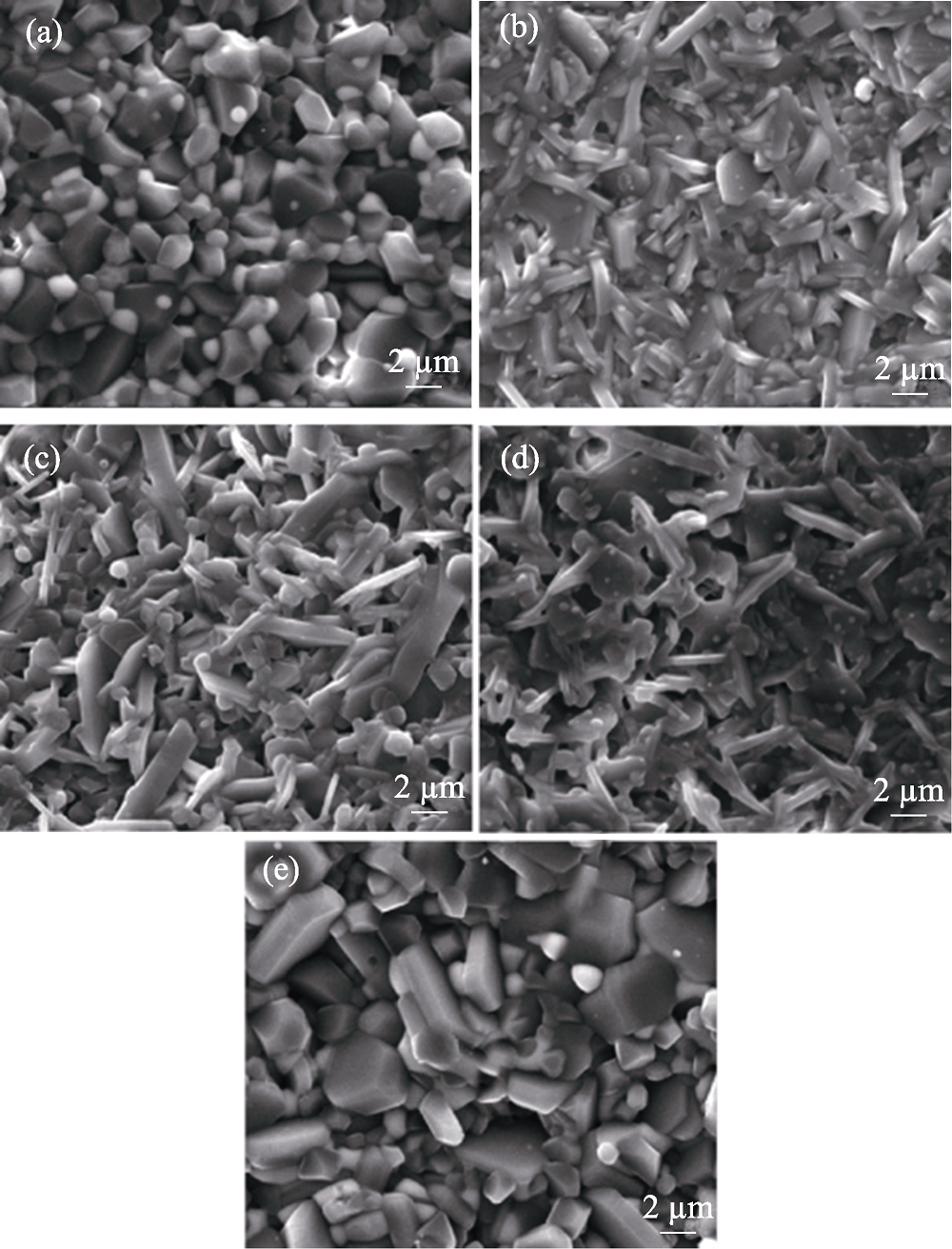

图8 Na2CO3含量对1600 ℃微波烧结得到的样品表面形貌的影响[63]

Fig. 8 Effect of Na2CO3 content on the surface morphology of the samples obtained by microwave sintering at 1600 ℃[63] (a) 3%; (b) 5%; (c) 7%; (d) 9%

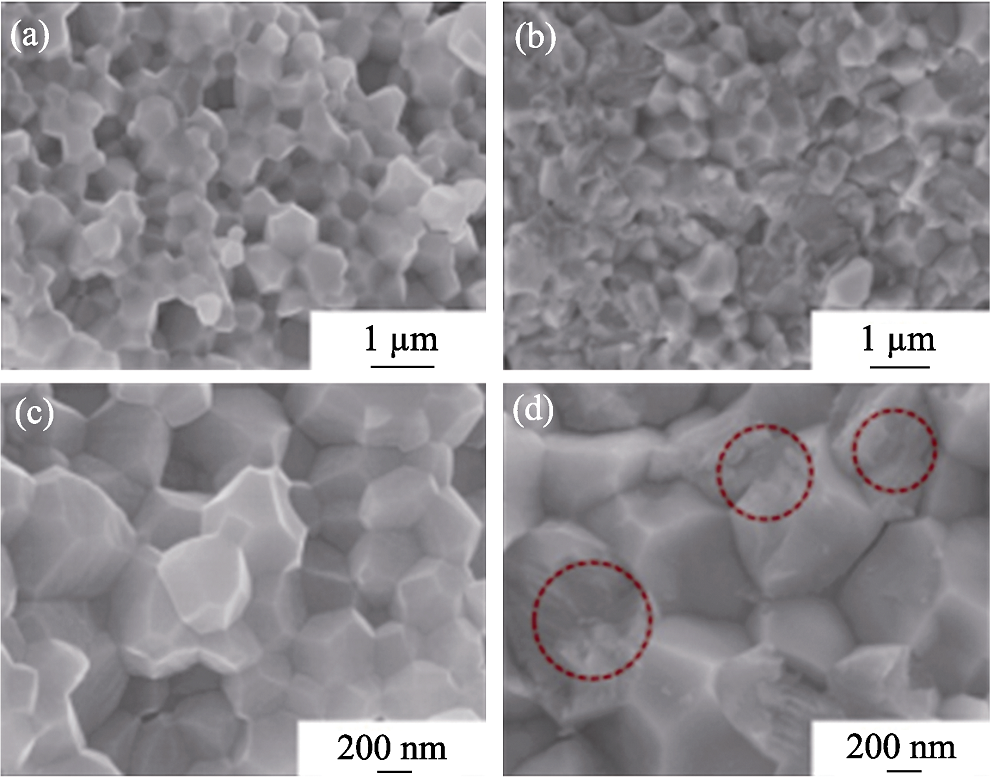

图9 1550 ℃烧结3Y-ZrO2陶瓷的断口SEM照片[70]

Fig. 9 SEM images of fracture of 3Y-ZrO2 ceramic after sintering at 1550 ℃[70] (a, c) Microwave sintering; (b, d) Conventional sintering

图10 不同摩尔分数La2O3掺杂ZTA陶瓷的SEM照片[31]

Fig. 10 SEM images of ZTA ceramics doped with different molar contents of La2O3[31] (a-d) Microwave sintering at 1550℃ for 30 min at La2O3 content of (a) 0, (b) 1.5%, (c) 3%, and (d) 5%; (e) Conventional sintering at 1600℃ for 3 h at La2O3 content of 1.5%

图11 不同温度下微波烧结Al2O3-SiC (~5 μm)试样的断口形貌[86]

Fig. 11 Fracture morphologies of Al2O3-SiC (~5 μm) specimens sintered by microwave at different temperatures[86] (a) 1350 ℃; (b) 1400 ℃; (c) 1450 ℃; (d) 1500 ℃

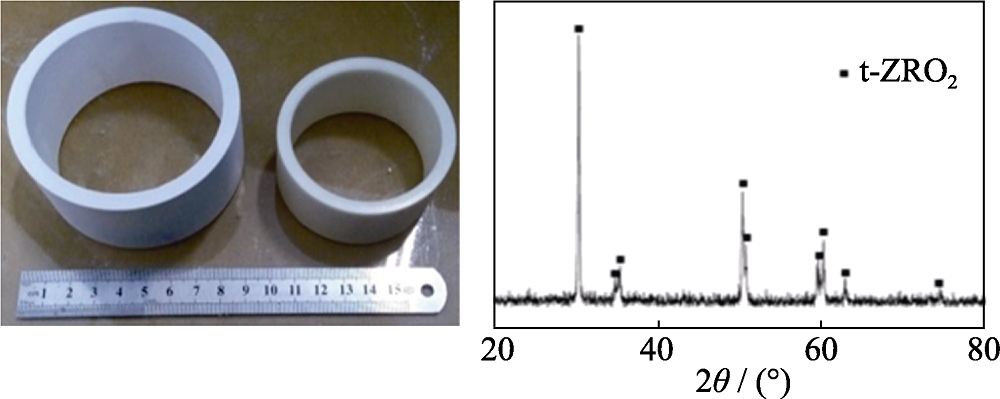

图13 氧化锆陶瓷环微波烧结前(左)后(右)实物对比照片及烧结后的XRD图谱[88]

Fig. 13 Comparison picture of zirconia ceramic ring before (left) and after (right) microwave sintering, and its XRD pattern after sintering[88]

| [1] | URKOVI L, VESELI R, GABELICA I, et al. A review of microwave-assisted sintering technique. Transactions of Famena, 2021, 45(1): 1-16. |

| [2] | 田永赉, 陶金陵, 郭景坤. 新型微波烧结陶瓷装置的研制. 科学通报, 1990, 21: 1641-1643. |

| [3] | SUTTON W H. Microwave processing of ceramics-an overview. MRS Online Proceeding Library Archive, 1992, 269: 3-20 |

| [4] | AGRAWAL D. Microwave sintering of ceramics, composites and metal powders. Sintering of Advanced Materials, 2010: 222-248. |

| [5] |

BINNER D J. Microwave processing of materials. Materials and Design, 1991, 12(4): 231.

DOI URL |

| [6] |

Yl A, JZA B, BING D A. Transparent MgAl2O4ceramics prepared by microwave sintering and hot isostatic pressing. Ceramics International, 2020, 46(16): 25738-25740.

DOI URL |

| [7] |

THRIDANDAPANI R R, FOLZ D C, CLARK D E. Effect of electric field (2.45 GHz) on sintering behavior of fully stabilized zirconia. Journal of the European Ceramic Society, 2015, 35(7): 2145-2152.

DOI URL |

| [8] | BROSNANR K H, MESSING G L, AGRAWAL D K. Microwave sintering of alumina at 2.45 GHz. 104th Meeting of the American Ceramic Society, 2003, 86(8): 1308-1312. |

| [9] | CHAIX J M. Microwave sintering of ceramics. Reference Module in Materials Science and Materials Engineering, 2020, 1: 327-341. |

| [10] | BORRELL A, SALVADOR M D. Advanced ceramic materials sintered by microwave technology. Sintering Technology-Method and Application, 2018: 3-24. |

| [11] |

STUART H. Ceramic processing and sintering. Materials & Design, 1996, 17(1): 55-56.

DOI URL |

| [12] | LAKSHMANAN A. Sintering to transparency of polycrystalline ceramic materials. Sintering of Ceramics-New Emerging Techniques, 2012, 16: 530-552. |

| [13] |

MANIERE C, ZAHRAH T, OLEVSKY E A. Inherent heating instability of direct microwave sintering process: sample analysis for porous 3Y-ZrO2. Scripta Materialia, 2017, 128: 49-52.

DOI URL |

| [14] |

MANIERE C, ZAHRAH T, OLEVSKY E A. Fully coupled electromagnetic-thermal-mechanical comparative simulation of direct vs hybrid microwave sintering of 3Y-ZrO2. Journal of the American Ceramic Society, 2017, 100(6): 2439-2450.

DOI URL |

| [15] |

HALIM A, SUDIN I, WAN F, et al. Formation of yttria aluminium garnet by microwave sintering. Materials Science Forum, 2020, 1010: 222-227.

DOI URL |

| [16] | VLEUGELS J, DEURSEN J V, ROEY O V, et al. Hybrid microwave sintering of titanium biomedical implants. 13th International Conference on Microwave and High Frequency Heating, France, 2011: 305-308. |

| [17] | BINNER J, VAIDHYANATHAN B, CARNEY T. Microwave hybrid sintering of nanostructured YSZ ceramics. Advances in Science and Technology, 2006, 45: 835-844. |

| [18] |

AKINWEKOMI A D, YEUNG K W, TANG C Y, et al. Finite element simulation of hybrid microwave sintering based on power approach. International Journal of Advanced Manufacturing Technology, 2020, 110(9/10): 1-13.

DOI URL |

| [19] |

HEUGUET R, MARINEL S, THUAULT A, et al. Effects of the susceptor dielectric properties on the microwave sintering of alumina. Journal of the American Ceramic Society, 2013, 96(12): 3728-3736.

DOI URL |

| [20] |

DUBE D, RAMESH P, CHENG J, et al. Experimental evidence of redistribution of fields during processing in a high-power microwave cavity. Applied Physics Letters, 2004, 85(16): 3632-3634.

DOI URL |

| [21] |

PIAN X X, FAN B B, CHEN H, et al. Preparation of m-ZrO2compacts by microwave sintering. Ceramics International, 2014, 40(7): 10483-10488.

DOI URL |

| [22] | YADOJI P, PEELAMEDU R, AGRAWAL D, et al. Microwave sintering of Ni-Zn ferrites: comparison with conventional sintering. Materials Science & Engineering B, 2003, 98(3): 269-278. |

| [23] |

LEONELLI C, VERONESI P, DENTI L, et al. Microwave assisted sintering of green metal parts. Journal of Materials Processing Technology, 2008, 205(1): 489-496.

DOI URL |

| [24] |

ROY R, AGRAWAL D, CHENG J P, et al. Full sintering of powdered-metal bodies in a microwave field. Nature, 1999, 399: 668-670.

DOI URL |

| [25] |

FAN S H, ZHENG H, GAO Q C, et al. Preparation of Al2O3-mullite thermal insulation materials with AlF3 and SiC as aids by microwave sintering. International Journal of Applied Ceramic Technology, 2020, 17(5): 2250-2258.

DOI URL |

| [26] |

SONG X Y, LIU X M, ZHANG J X. Neck formation and self-adjusting mechanism of neck growth of conducting powders in spark plasma sintering. Journal of American Ceramic Society, 2006, 89: 494-500.

DOI URL |

| [27] |

ZHANG X Y, GAO Q C, SONG B Z, et al. Effect of C: SiO2 ratio on heating behavior and photoluminescence property of SiC by microwave. Science of Advanced Materials, 2021, 13: 591-596.

DOI URL |

| [28] |

SHEN Z, JOHNSSON M, ZHE Z, et al. Spark plasma sintering of alumina. Journal of the American Ceramic Society, 2010, 85(8): 1921-1927.

DOI URL |

| [29] |

CHEN Y Q, LI S, LI W, et al. Effect of SiCp addition on microstructure and mechanical properties of ZTA ceramics by microwave sintering. Solid State Phenomena, 2018, 281: 217-223.

DOI URL |

| [30] |

GIL-FLORES L, SALVADOR M D, PENARANDA-FOLX F L, et al. Microstructure and mechanical properties of 5.8 GHz microwave-sintered ZrO2 /Al2O3 ceramics. Ceramics International, 2019, 45(14): 18059-18064.

DOI URL |

| [31] | ZHAO T, LU H, XIANG H, et al. Preparation of high purity α-Al2O3 particles derived from industrial waste solution via microwave calcining and seeding technique. Materials Research Express, 2018, 6(1): 1-11. |

| [32] |

LE T, WANG T, RAVINDRA A V, et al. Fast synthesis of submicron zeolite Y using microwave heating. Kinetics and Catalysis, 2021, 62(3): 436-444.

DOI URL |

| [33] |

VOLLATH D, SZABO D V, HAU J, et al. Synthesis and properties of ceramic nanoparticles and nanocomposites. Journal of the European Ceramic Society, 1997, 17(11): 1317-1324.

DOI URL |

| [34] | 戴长虹, 张显鹏, 张劲松, 等. 微波法合成AlN纳米微粉. 金属学报, 1996, 32(11): 1221-1226. |

| [35] | 曹传宝, 喻维杰, 彭定坤, 等. 微波等离子体化学气相淀积纳米级 ZrO2薄膜. 无机材料学报, 1992, 7(3): 323-328. |

| [36] | WILLERT-PORADA M, KRUMMEL T, ROHDE B. Ceramic powders generated by metallorganic and microwave processing. MRS Proc., 1992, 269: 199. |

| [37] | 彭金辉, Volla D. 微波加热在陶瓷材料中的应用. 稀有金属, 1997, 21(5): 363-365. |

| [38] |

LI J, TAKASHI S, MASAYOSHI F. Rapid carbothermal synthesis of nanostructured silicon carbide particles and whiskers from rice husk by microwave heating method. Advanced Powder Technology, 2013, 24(5): 838-843.

DOI URL |

| [39] |

TONY V C S, VOON C H, LEE C C, et al. Novel synthesis of silicon carbide nanotubes by microwave heating of blended silicon dioxide and multi-walled carbon nanotubes: the effect of the heating temperature. Ceramics International, 2016, 42(15): 17642-17649.

DOI URL |

| [40] |

LAI Y Q, SUN Z, JIANG L X, et al. Rapid sintering of ceramic solid electrolytes LiZr2(PO4)3 and Li1.2Ca0.1Zr1.9(PO4)3 using a microwave sintering process at low temperatures. Ceramics International, 2019, 45(8): 11068-11072.

DOI URL |

| [41] |

ENRIQUE C P, JENIFER S, ANAELISE M C, et al. Microwave synthesis of silica nanoparticles and its application for methylene blue adsorption, Journal of Environmental Chemical Engineering, 2018, 6(1): 649-659.

DOI URL |

| [42] |

ANA P, ANA S, DANIELA N, et al. Ultra-fast microwave synthesis of ZnO nanorods on cellulose substrates for UV sensor applications. Materials, 2017, 10(11): 1308.

DOI URL |

| [43] |

CHEN H, FAN B B, XIN Z, et al. Preparation of α-Al2O3 powder by microwave pyrolysis. Key Engineering Materials, 2014, 602-603: 88-92.

DOI URL |

| [44] | 张昕. 微波烧结Al2O3/SiC复合材料研究. 郑州: 郑州大学硕士学位论文, 2013. |

| [45] | 陈浩. 微波热解制备氧化锆纳米粉体的工艺及机理研究. 郑州: 郑州大学硕士学位论文, 2014. |

| [46] | HUANG X M, ZORMAN C. MEHREGANY A, et al. Nanodevice motion at microwave frequencies. Nature, 2003, 421(6922): 496-496. |

| [47] | PIERSON H O. Handbook of refractory carbides and nitrides. Noyes Publications, USA, 1996: 248-275. |

| [48] | HILLERY M T. Properties of silicon carbide. Engineering Science & Education Journal, 1997, 6(6): 212-212. |

| [49] |

WANG J K, ZHANG Y Z, LI J Y, et al. Catalytic effect of cobalt on microwave synthesis of β-SiC powder. Powder Technology, 2017, 317: 209-215.

DOI URL |

| [50] |

LIU S, WANG J G. Tunable magnetic properties of SiC obtained by microwave heating. Journal of Alloys and Compounds, 2018, 731: 369-374.

DOI URL |

| [51] | VOON C H, LIM B Y, GOPINATH S C B, et al. Green synthesis of silicon carbide nanowhiskers by microwave heating of blends of palm kernel shell and silica. IOP Conference Series: Materials Science and Engineering, 2016, 160(1): 012057. |

| [52] |

LI J, SHIRAI T, JI M F. Rapid carbothermal synthesis of nanostructured silicon carbide particles and whiskers from rice husk by microwave heating method. Advanced Powder Technology, 2013, 24(5): 838-843.

DOI URL |

| [53] |

ZHAN H J, ZHANG N, WU D. Controlled synthesis of β-SiC with a novel microwave sintering method. Materials Letters, 2019, 255(15): 126586.

DOI URL |

| [54] |

WANG J, HUANG S, LIU S, et al. EBSD characterization of the growth mechanism of SiC synthesized via direct microwave heating. Materials Characterization, 2016, 114: 54-61.

DOI URL |

| [55] | 郝斌, 刘剑, 刘进强. 微波烧结制备碳化硅晶须的影响因素. 材料热处理学报, 2013, 34(8): 1-5. |

| [56] | 解亚军. 微波合成SiC晶体的工艺研究. 郑州: 郑州大学硕士学位论文, 2016. |

| [57] |

SONG B, ZHAO B, FAN L, et al. Investigation on heating behavior during the preparation of SiC crystals by microwave sintering. International Journal of Applied Ceramic Technology, 2017, 14: 833-1025.

DOI URL |

| [58] |

WEI S, GUAN L, SONG B, et al. Seeds-induced synthesis of SiC by microwave heating. Ceramics International, 2019, 45: 9771-9775.

DOI URL |

| [59] |

SONG B, ZHAO B, LU Y, et al. Investigation on the growth mechanism of SiC whiskers during microwave synthesis. Physical Chemistry Chemical Physics, 2018, 20: 25799-25805.

DOI URL |

| [60] |

ZHANG X, SONG B, ZHANG Y, et al. Influences of pre-forming on preparation of SiC by microwave heating. Ceramics International, 2018, 44: 21309-21313.

DOI URL |

| [61] | LI X, FAN B, LU H, et al. Investigation on preparation of Na0.5K0.5NbO3 nanoparticles by microwave heating method. Materials Research Express, 2018, 5(11): 1-10. |

| [62] | 李杏瑞, 范冰冰, 邵刚, 等. 微波法制备CaZrO3掺杂铌酸钾钠压电粉体研究. 第十九届全国高技术陶瓷学术年会论文集, 湖北, 2016: 17. |

| [63] | 张世豪, 范冰冰, 高前程, 等. 反应温度和添加剂含量对微波合成碳化硼微观形貌的影响. 人工晶体学报, 2017, 46(3): 463-467. |

| [64] | 种小川, 肖国庆, 丁冬海, 等. 碳化硼粉体合成方法的研究进展. 材料导报, 2019, 33(15): 2524-2531. |

| [65] | CHAN D A, DASGUPTA S, BOSE S, et al. Microwave sintering of calcium phosphate ceramics. Materials Science and Engineering, 2009, 29: 1144-1149. |

| [66] |

KO A, YL A, PM B, et al. Influence of microwave sintering on electrical properties of BCTZ lead free piezoelectric ceramics. Journal of the European Ceramic Society, 2020, 40(4): 1212-1216.

DOI URL |

| [67] |

RAMESH P, ZULKIFLI N, TAN C Y, et al. Comparison between microwave and conventional sintering on the properties and microstructural evolution of tetragonal zirconia. Ceramics International, 2018, 44: 8922-8927.

DOI URL |

| [68] |

MANGKONSU C, KUNIO I, BUNHAN L, et al. The effect of microwave sintering on the microstructure and properties of calcium phosphate ceramic. Procedia Chemistry, 2016, 19: 498-504.

DOI URL |

| [69] | SAHA R. Microwave sintering of ceramics for dentistry: part 2, Dentistry, 2015, 5(7): 5-8. |

| [70] |

CHEN Y, FAN B, YANG B, et al. Microwave sintering and fracture behavior of zirconia ceramics. Ceramics International, 2019, 45(14): 17675-17680.

DOI URL |

| [71] |

CROQUESEL J, CARRY C P, CHAIX J M, et al. Direct microwave sintering of alumina in a single mode cavity: magnesium doping effects. Journal of the European Ceramic Society, 2018, 38(4): 1841-1845.

DOI URL |

| [72] |

CROQUESEL J, BOUVARD D, CHAIX J M, et al. Direct microwave sintering of pure alumina in a single mode cavity: grain size and phase transformation effects. Acta Materialia, 2016, 116: 53-62.

DOI URL |

| [73] | FIGIEL P, ROZMUS M, SMUK B. Properties of alumina ceramics obtained by conventional and non-conventional methods for sintering ceramics. Journal of Achievements in Materials and Manufacturing Engineering, 2011, 48(1): 71-78. |

| [74] | MOHAMED A M A, MATLI P R, RAJURU R R. Microwave fast sintering of double perovskite ceramic materials. Advanced Ceramic Processing, 2015. |

| [75] |

BORRELL A, SALVADOR M D, PENARANDA-FOIX F L, et al. Microwave sintering of zirconia materials: mechanical and microstructural properties. International Journal of Applied Ceramic Technology, 2013, 10(2): 313-320.

DOI URL |

| [76] |

SHUKLA M, GHOSH S, DANDAPAT N, et al. Comparative study on conventional sintering with microwave sintering and vacuum sintering of Y2O3-Al2O3-ZrO2 ceramics. Journal of Materials Science and Chemical Engineering, 2016, 4(2): 71-78.

DOI URL |

| [77] |

CHENG J, AGRAWAL D, ZHANG Y, et al. Microwave sintering of transparent alumina. Materials Letters, 2002, 56(4): 587-592.

DOI URL |

| [78] |

WEI C, FU C, HU W, et al. Effects of microwave sintering power on microstructure, dielectric, ferroelectric and magnetic properties of bismuth ferrite ceramics. Journal of Alloys and Compounds, 2013, 554(6): 64-71.

DOI URL |

| [79] | 郑立辉, 程寓, 汪家傲, 等. 基于辅热材料的微波烧结陶瓷刀具温度场研究. 中国陶瓷工业, 2021, 28: 1-4. |

| [80] |

YANG M, WANG H, CHEN R, et al. Comparison of the microwave and conventional sintering of Li2TiO3 ceramic pebbles. Ceramics International, 2018, 44: 19672-19677.

DOI URL |

| [81] |

CURTO H, THUAULT A, JEAN F, et al. Coupling additive manufacturing and microwave sintering: a fast processing route of alumina ceramics. Journal of the European Ceramic Society, 2020, 40(7): 2548-2554.

DOI URL |

| [82] |

ALVARO P, MARLA D. S, FELIPE L, et al. Effect of microwave sintering on microstructure and mechanical properties in Y-TZP materials used for dental applications. Ceramics International, 2015, 41(5): 7125-7132.

DOI URL |

| [83] |

MWKA B, YIKB C, MAHA B, et al. Microwave hybrid sintering of Al2O3 and Al2O3-ZrO2 composites, and effects of ZrO2 crystal structure on mechanical properties, thermal properties, and sintering kinetics. Ceramics International, 2020, 46(7): 9002-9010.

DOI URL |

| [84] |

XIAO C, HAN B B. Preparation of porous silicon nitride ceramics by microwave sintering and its performance evaluation. Journal of Materials Research and Technology, 2019, 8(6): 5984-5995.

DOI URL |

| [85] |

XU W, YIN Z, YUAN J, et al. Effects of sintering additives on mechanical properties and microstructure of Si3N4 ceramics by microwave sintering. Materials Science and Engineering A, 2016, 684(1): 127-134.

DOI URL |

| [86] |

DANG X, WEI M, ZHANG R, et al. Crucial effect of SiC particles on in situ synthesized mullite whisker reinforced Al2O3-SiC composite during microwave sintering. Processing and Application of Ceramics, 2017, 11(2): 106-112.

DOI URL |

| [87] |

DANG X, WEI M, FAN B B, et al. Effects of in situ synthesized mullite whisker on mechanical properties of Al2O3-SiC composite by microwave sintering. Materials Research Express, 2017, 4(6): 065015.

DOI URL |

| [88] | 范冰冰, 陈勇强, 李红霞, 等. 一种同步补偿微波混合共烧结方法. CN106673671A |

| [89] |

CHEN Y, FAN B, GANG S, et al. Preparation of large size ZTA ceramics with eccentric circle shape by microwave sintering. Journal of Advanced Ceramics, 2016, 5(4): 291-297.

DOI URL |

| [90] |

EXARE C, KIAT J M, GUIBLIN N, et al. Structural evolution of ZTA composites during synthesis and processing. Journal of the European Ceramic Society, 2015, 35(4): 1273-1283.

DOI URL |

| [91] |

PIAN X, SHAO G, FAN B, et al. Rapid densification of SiC ceramic rollers by microwave sintering. Advances in Applied Ceramics, 2015, 114: 28-32.

DOI URL |

| [1] | 魏相霞, 张晓飞, 徐凯龙, 陈张伟. 增材制造柔性压电材料的现状与展望[J]. 无机材料学报, 2024, 39(9): 965-978. |

| [2] | 杨鑫, 韩春秋, 曹玥晗, 贺桢, 周莹. 金属氧化物电催化硝酸盐还原合成氨研究进展[J]. 无机材料学报, 2024, 39(9): 979-991. |

| [3] | 刘鹏东, 王桢, 刘永锋, 温广武. 硅泥在锂离子电池中的应用研究进展[J]. 无机材料学报, 2024, 39(9): 992-1004. |

| [4] | 黄洁, 汪刘应, 王滨, 刘顾, 王伟超, 葛超群. 基于微纳结构设计的电磁性能调控研究进展[J]. 无机材料学报, 2024, 39(8): 853-870. |

| [5] | 陈乾, 苏海军, 姜浩, 申仲琳, 余明辉, 张卓. 超高温氧化物陶瓷激光增材制造及组织性能调控研究进展[J]. 无机材料学报, 2024, 39(7): 741-753. |

| [6] | 王伟明, 王为得, 粟毅, 马青松, 姚冬旭, 曾宇平. 以非氧化物为烧结助剂制备高导热氮化硅陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 634-646. |

| [7] | 蔡飞燕, 倪德伟, 董绍明. 高熵碳化物超高温陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 591-608. |

| [8] | 吴晓晨, 郑瑞晓, 李露, 马浩林, 赵培航, 马朝利. SiCf/SiC陶瓷基复合材料高温环境损伤原位监测研究进展[J]. 无机材料学报, 2024, 39(6): 609-622. |

| [9] | 赵日达, 汤素芳. 多孔碳陶瓷化改进反应熔渗法制备陶瓷基复合材料研究进展[J]. 无机材料学报, 2024, 39(6): 623-633. |

| [10] | 方光武, 谢浩元, 张华军, 高希光, 宋迎东. CMC-EBC损伤耦合机理及一体化设计研究进展[J]. 无机材料学报, 2024, 39(6): 647-661. |

| [11] | 张幸红, 王义铭, 程源, 董顺, 胡平. 超高温陶瓷复合材料研究进展[J]. 无机材料学报, 2024, 39(6): 571-590. |

| [12] | 张慧, 许志鹏, 朱从潭, 郭学益, 杨英. 大面积有机-无机杂化钙钛矿薄膜及其光伏应用研究进展[J]. 无机材料学报, 2024, 39(5): 457-466. |

| [13] | 李宗晓, 胡令祥, 王敬蕊, 诸葛飞. 氧化物神经元器件及其神经网络应用[J]. 无机材料学报, 2024, 39(4): 345-358. |

| [14] | 鲍可, 李西军. 化学气相沉积法制备智能窗用热致变色VO2薄膜的研究进展[J]. 无机材料学报, 2024, 39(3): 233-258. |

| [15] | 胡梦菲, 黄丽萍, 李贺, 张国军, 吴厚政. 锂/钠离子电池硬碳负极材料的研究进展[J]. 无机材料学报, 2024, 39(1): 32-44. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||